- Home

- Starch Paste Kettle

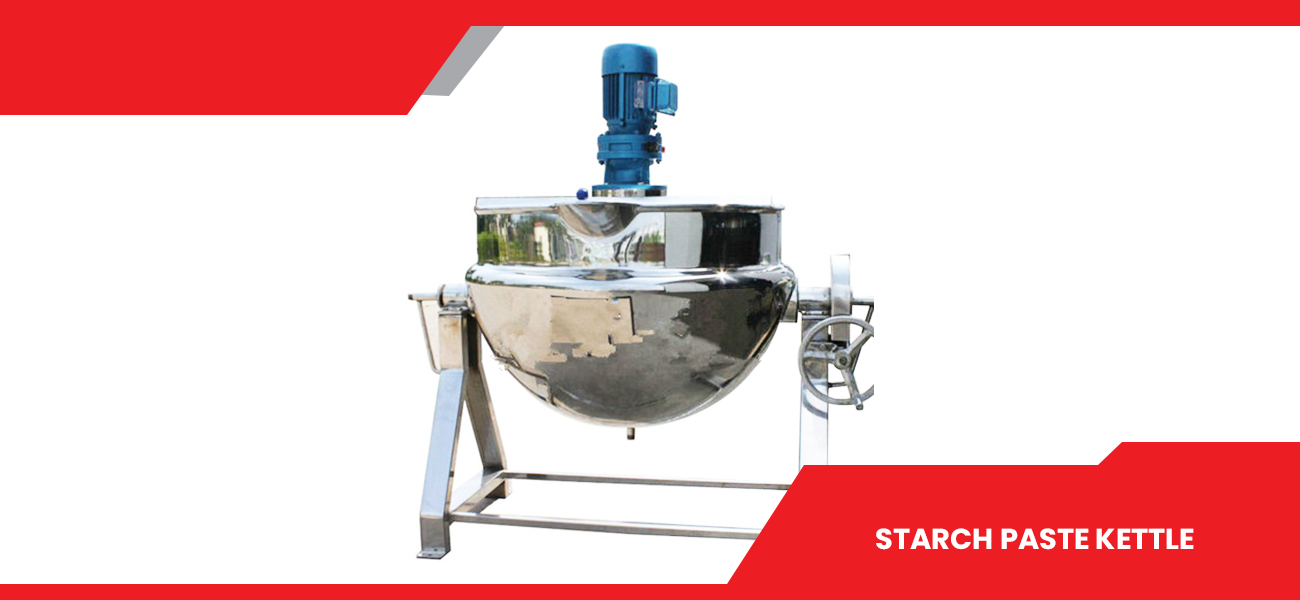

Starch Paste Kettle

Applications :

“ PHARMA FAB INDUSTRIES “ Starch Paste Kettles is used for preparation of Starch Paste for Pharmaceuticals, Cosmetics, Food & Dairy Industries.

Process :

- Hemispherical shape ensures that the Heating of the Starch Paste is Uniform & gets more Surface area.

- The Tilting type arrangement Ensures ease in unloading the Paste into any container or vessel.

- The Starch is poured in the kettle and water is added till desired thickness is achieved.

- The Kettle is jacketed & is heated till the Starch Melts . A Thick Paste is achieved.

- This Paste can be agitated either manually or with The Help of Anchor Type agitator which will constantly stir.

- The Paste so that there will no lumps formation and proper mixing is achieved.

- Temperature can be set to desired temp by adjusting the thermostat connected to digital temperature controller. The Temperature can be seen in the dial thermometer provided.

Salient Features available :

- Starch Paste Kettle is available From 10 Ltrs to 2000 Ltrs Capacity. Available in Lab model and Production model also .

- Design as per GMP and cGMP model

- MOC : SS 304 , SS 316 , SS 316 L

- Contact parts SS 316 / 316L and Non Contact parts SS 304

- Hemispherical bowl with either steam, electrical or oil heating options.

- Options available for starch paste with agitator / without agitator.

- Tilting is provided for easy in unloading of final products.

- Higher capacity models available without tilting but with bottom outlet.

- Hemispherical design helps in for proper mixing of paste

- Jacket provided with steam/thermic/fluid heating arrangement

- Driven via motor and gear box assembly mounted on top

- Tilting arrangement for kettle is provided for discharge for starch paste

- Anchor type impeller design for proper mixing of paste

- Safety is provided by earthing system

Starch Paste Kettle Specifications :

- The Kettle is hemispherical type bowl with either steam / Oil / Water heating Jacket will be provided.

- The Kettle is manufactured SS 316 / SS316L / S.S. 304 .

- Starch Paste Kettle frame work is made out of S.S. 304 Rectangular Pipes and will be an independent resting type frame work where no foundation will be required.

- Oil / water heater fitted at the back bottom side of the Kettle. The Kettle have a worm type arrangement for tilting. A temperature controller & a temp Indicator is provided for temperature control & Indication. The Kettle is Insulated with thick glass wool

- Externally and Internally of Starch Paste Kettle will be mirror finish .

Optional Features Available

- Starch Paste Kettle is built in stirrer arrangement with lifting & lowering device

- Our Starch Paste Kettle is equipped with Steam Heating / Electric heating with all connections factory fitted

- Non Tilting type with bottom discharge models are also available.

- Flameproof construction

- VFD ( if it is starch paste with agitator)